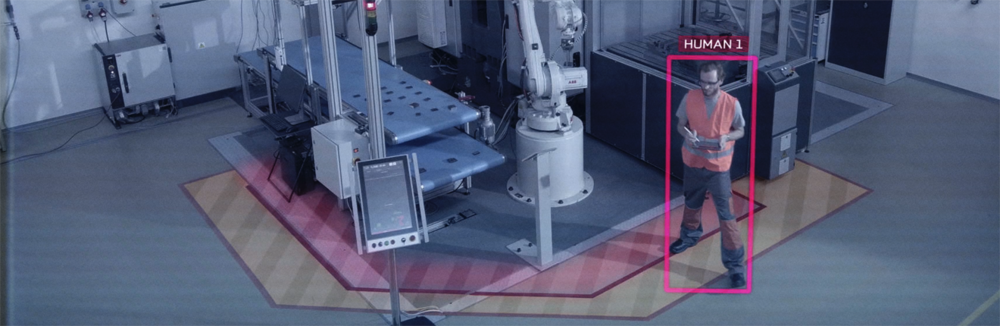

The Invanta system uses artificial intelligence and machine vision in industrial safety and can proactively prevent dangerous situations by reacting immediately.

The most common use cases to secure are robotic workplaces and the surroundings of dangerous machines. The company is also involved in detecting the correct use of protective equipment (PPE) or, for example dealing with the AGV safety of pallet collection points, where the system can relay information to the AGV control system and react accordingly.

The small box has the character of a sensor and contains a camera, which captures an image, most often of the surroundings of the dangerous machine. It also has a computing unit with a neural network that analyses in real time what is happening around the machine and also contains an electronic module that communicates with the machine.

The biggest advantage is the sensor's ability to recognize what is human and what is material. Invanta sensor is then able to react to what is happening in production. For example, if a forklift is picking up material from the production line, there is no need to stop the line unnecessarily. But if the operator gets off the truck and personally enters the danger zone, the system responds by stopping immediately. There is not monitored just the boundary line around the machine, but the entire interior area. It's also an option for outdoor use - that's where traditional systems fail due to falling leaves, snow or flying insects.

The most common use cases to secure are robotic workplaces and the surroundings of dangerous machines. The company is also involved in detecting the correct use of protective equipment (PPE) or, for example dealing with the AGV safety of pallet collection points, where the system can relay information to the AGV control system and react accordingly.

The small box has the character of a sensor and contains a camera, which captures an image, most often of the surroundings of the dangerous machine. It also has a computing unit with a neural network that analyses in real time what is happening around the machine and also contains an electronic module that communicates with the machine.

The biggest advantage is the sensor's ability to recognize what is human and what is material. Invanta sensor is then able to react to what is happening in production. For example, if a forklift is picking up material from the production line, there is no need to stop the line unnecessarily. But if the operator gets off the truck and personally enters the danger zone, the system responds by stopping immediately. There is not monitored just the boundary line around the machine, but the entire interior area. It's also an option for outdoor use - that's where traditional systems fail due to falling leaves, snow or flying insects.